This text explains the difference between torsion and extension springs. Torsion springs twist to store and release energy, ideal for quick, rotational force tasks like garage door openers. Extension springs straighten under tension, suitable for gradual force deployment in applications like car shocks. Understanding these structural differences is key to selecting the right spring for specific needs.

“Explore the intricate world of emergency torsion spring coiling, a critical process in understanding the unique mechanics of torsional and extensional springs. This article delves into the fundamentals of torsion springs—their types and distinct applications—and offers a comprehensive comparison with extension springs.

Learn about the crucial differences between these two spring categories, highlighting their structural, functional, and practical distinctions. By the end, readers will grasp why emergency coiling is essential for specialized applications.”

- Understanding Torsion Springs: Basics and Types

- Extension Springs: Definition and Common Applications

- The Key Differences Between Torsion and Extension

- Emergency Coiling: A Critical Process Explained

Understanding Torsion Springs: Basics and Types

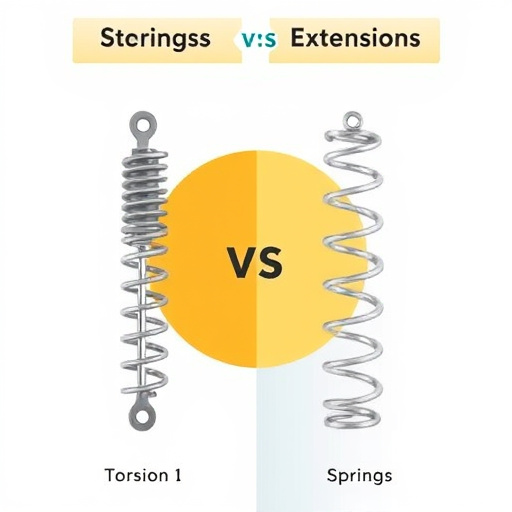

Torsion springs are mechanical devices that store and release energy through a helical wire design, capable of exerting a high force in a controlled manner. Unlike extension springs that pull or push in a linear motion, torsion springs operate by twisting around their axis, making them ideal for applications requiring rotational force. The fundamental difference between torsion and extension springs lies in their function; while extension springs manage tension along their length, torsion springs concentrate this energy into a rotational force.

There are various types of torsion springs, each with specific characteristics tailored to different needs. From compact, lightweight options suitable for precision machinery to robust, high-torque springs used in automotive and industrial applications, the versatility of torsion springs is remarkable. Understanding torque ratings explained is crucial when selecting the appropriate spring for an auto repair service or any specialized spring solution. If you require expert assistance with your spring coiling needs, give us a call at Garage door panel replacement.

Extension Springs: Definition and Common Applications

Extension springs are a type of compression coil designed to store and release energy when stretched or compressed. Unlike torsion springs, which twist and return to their original shape, extension springs straighten out as they compress, making them ideal for applications that require a linear force. These versatile springs can be found in various everyday items like garage door openers, car shocks, and even in simple home repair forums where DIY enthusiasts discuss torsion spring repairs and spring replacement specialists.

The key difference between torsion and extension springs lies in their structural design and function. Torsion springs twist around a central axis, providing rotational force, while extension springs work along a linear axis, offering tension to pull or push objects. When you need reliable and efficient spring systems for tasks ranging from opening heavy garage doors to maintaining vehicle suspension, consider the specific requirements of your application. For expert advice on torsion spring repairs or to discuss tailored solutions, give us a call at Garage door spring replacement.

The Key Differences Between Torsion and Extension

Torsion springs and extension springs are two distinct types of springs with unique characteristics and applications. The key difference lies in their design and how they store and release energy. Torsion springs, often found in garage door openers, operate by twisting around a central axis when compressed or extended. This design allows them to store significant amounts of energy efficiently and release it quickly, making them ideal for tasks requiring sudden, powerful movements. On the other hand, extension springs, commonly used in various mechanical devices and home repairs like window catches and springs on gates, work by straightening out from their coiled state. They offer a more gradual force deployment compared to torsion springs, making them suitable for applications that demand consistent tension or support over time.

While extension spring uses in home repairs and metalworking classes are prevalent, torsion springs have specific advantages. For instance, local auto parts stores often stock various torsion springs for diverse automotive applications. Even if you’re not a professional, understanding the difference between these springs can help with basic maintenance. For more complex tasks or if you need expert advice, visit us at Garage door opener installation experts.

Emergency Coiling: A Critical Process Explained

Emergency Coiling is a critical process that involves the rapid and controlled winding of torsion springs, a key component in various mechanical systems including garage doors. Unlike extension springs that stretch when pulled, torsion springs twist under tension, storing energy for subsequent release. Understanding this difference is crucial when it comes to tasks like learning to make springs or navigating home repair forums.

When an emergency situation arises, such as a malfunctioning garage door, the ability to coil a torsion spring becomes a matter of safety and functionality. The best garage door service serving Vail emphasizes the importance of precise techniques to ensure these springs can withstand sudden stress without failing. This process requires specialized tools and knowledge to adjust tension, manage coil diameter, and maintain the spring’s structural integrity, ultimately preventing accidents and securing efficient operation.

In understanding the distinct roles of torsion and extension springs, especially in emergency coiling scenarios, it’s clear that each type serves unique purposes. Torsion springs, with their ability to store energy rotationally, are ideal for applications requiring controlled releases, while extension springs, characterized by their linear stress-strain relationship, excel in situations demanding rapid, straight-line movement. Knowing the difference between these spring types is crucial for efficient problem-solving and effective emergency coiling processes.