The text compares torsion and extension springs, highlighting their distinct structures and applications. Torsion springs, with helical wire designs, store energy through twisting, ideal for high torque tasks like garage doors. Extension springs, using flexible alloys, store energy by stretching/compressing, providing controlled linear force in various devices and equipment. Understanding these differences is key to selecting the right spring type based on specific energy storage and force needs, promoting sustainable manufacturing practices, and optimizing recycling efforts. The difference between torsion and extension springs explained is crucial for effective maintenance, replacement, and leveraging their unique strengths in diverse applications.

Understanding the distinction between torsion and extension springs is key for selecting the right suspension component. This article delves into the fundamental differences between these two types of springs, exploring their unique structures, material choices, force dynamics, and applications across industries.

From basic structure and function comparisons to maintenance best practices, we’ll break down how these variations impact performance and longevity. Learn about the distinct advantages of each type and discover which excels in specific scenarios, ultimately providing a clear explanation of the difference between torsion and extension springs explained through expert insights.

- Basic Structure and Function Comparison

- Material and Manufacturing Differences

- Force and Energy Storage Behavior

- Applications in Various Industries

- Maintenance and Replacement Considerations

Basic Structure and Function Comparison

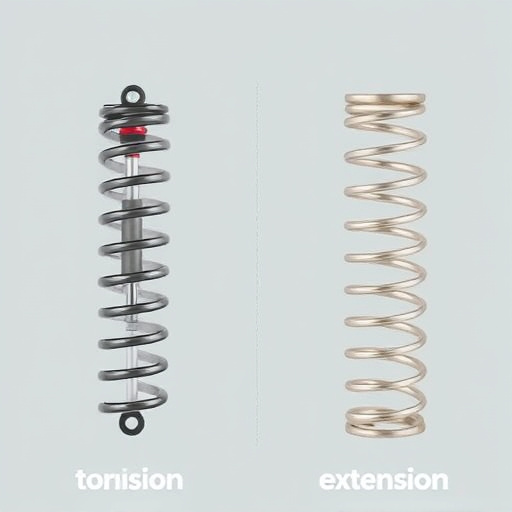

The difference between torsion and extension springs lies in their basic structure and function, which directly impacts their applications. Torsion springs, as the name suggests, utilize a helical wire to store energy by twisting around a central axis. This design makes them highly versatile for controlling and releasing torque, making them a popular choice in various industries like automotive, hardware, and even home improvement. For instance, torsion springs are commonly found in garage door systems, providing the necessary force for smooth operation.

On the other hand, extension springs operate by stretching or compressing along their longitudinal axis. They consist of a coiled wire with a hook on one end that can extend or retract when a force is applied. These springs are often used in traditional techniques where a linear force is required, such as in mechanical devices, farming equipment, and even everyday items like ballpoint pens. Unlike torsion springs, extension springs are not typically used for torque control but rather for precise motion and force application, making them an essential component in many mechanical and manufacturing processes. Find us at The best garage door service serving Casas Adobes for expert advice on choosing the right spring type for your needs.

Material and Manufacturing Differences

The fundamental difference between torsion and extension springs lies in their material composition and manufacturing processes. Torsion springs, often found in garage doors and mechanical devices, are crafted from durable steel wire, tightly coiled to store energy. This design allows them to withstand high torques and provide consistent performance over time. On the other hand, extension springs, commonly utilized in applications like car suspensions and industrial machinery, are made from flexible metal alloys, such as music wire or stainless steel. They operate by stretching and contracting, offering precise force and control.

These material variations significantly impact their functionality. Torsion springs excel at resisting rotational forces, making them ideal for systems requiring constant torque. In contrast, extension springs are designed to handle linear motion and provide a controlled release of energy. Local hardware store employees often emphasize these differences when advising customers on spring selection for specific projects, promoting local sustainability initiatives through responsible manufacturing practices, and even highlighting local spring innovation that has made such specialized components more accessible. Find us at Reliable garage door tune-ups for expert insights into these essential mechanical elements.

Force and Energy Storage Behavior

Torsion and extension springs exhibit distinct behaviors when it comes to force and energy storage. Torsion springs, characterized by their spiral structure, store energy by twisting. This mechanism allows them to deliver a high torque with relative ease, making them ideal for applications requiring sudden, powerful movements like in door catches or vehicle hoods. On the other hand, extension springs work on a compressional principle. They store energy as they are stretched, and this stored energy is then released when needed, producing a linear force. This makes them suitable for tasks demanding consistent force over a certain distance, such as in automotive suspensions or mechanical engineering projects involving soilless farming systems.

Understanding these fundamental differences is crucial when selecting springs for specific applications. For instance, if you’re looking to recycle old springs for eco-friendly initiatives like soilless farming, knowing the unique energy storage capabilities of each type can help optimize their utilization. Similarly, those involved in preventative maintenance plans for machinery should consider the spring’s behavior to ensure optimal performance and longevity, ensuring that the chosen spring aligns with the mechanical demands of the task at hand. Find us at Preventative maintenance plans for more insights into these topics.

Applications in Various Industries

The difference between torsion and extension springs goes beyond their physical structure; it directly impacts their applications across various industries. Torsion springs, known for their coiled design, offer consistent force over a defined angle, making them ideal for controlling doors, windows, and other mechanical movements. This is evident in the smooth operation of garage door opener systems, where torsion springs bear the weight and provide balanced movement.

On the other hand, extension springs extend or contract under tension, delivering a powerful force in a linear motion. They find extensive use in home repairs, from securing screens to adjusting furniture. Commercial extension spring applications are diverse, ranging from manufacturing machinery to vehicle components. Their ability to store and release energy efficiently makes them valuable for tasks requiring sudden force, such as in power tools or automobile suspensions. While extension spring troubleshooting may involve issues like corrosion or fatigue, their versatility remains unmatched, especially when compared to the more specialized torsion springs. Visit us at Garage door opener installation experts for a deeper dive into these mechanical marvels and how they shape our daily lives.

Maintenance and Replacement Considerations

When considering maintenance and replacement for your spring needs, understanding the key differences between torsion and extension springs is essential. These two types serve distinct purposes in various applications, from garage doors to industrial machinery. Knowing their unique characteristics helps in making informed decisions regarding upkeep and upgrades.

Torsion springs, renowned for their cylindrical shape, are designed to handle high loads and provide consistent force over a specific angle. Regular maintenance involves periodic lubrication and adjustments to ensure optimal performance. In contrast, extension springs, known for their linear movement, are typically used in situations requiring precise force control at a specific extended length. Their care often includes regular inspection for signs of wear or damage, especially in residential spring installation scenarios, and timely replacement to avoid safety risks. Custom design options available from reputable brands like The best garage door service serving Casas Adobes can cater to specific needs, ensuring both functionality and longevity. Spring cleaning donations, while not a typical concern for these springs, highlight the importance of proper care in maintaining their efficiency.

Understanding the subtle yet significant differences between torsion and extension springs is crucial for selecting the right type of spring for specific applications. From their distinct structures and material choices to their unique force dynamics, each has its own strengths and limitations. Knowing these variations enables engineers and manufacturers to make informed decisions, ensuring optimal performance, efficiency, and longevity across diverse industries where springs play a vital role. By grasping the “difference between torsion and extension springs explained” in this comprehensive overview, readers are equipped to navigate the selection process with newfound confidence.